2021-10-23 15:00:38

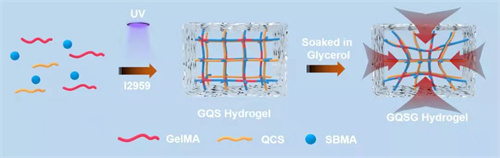

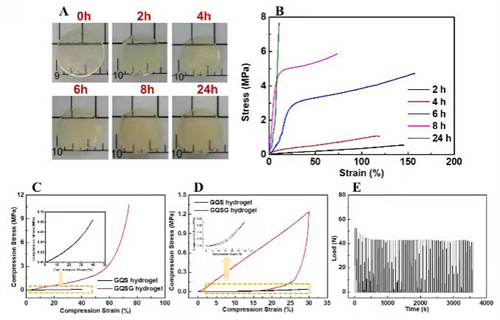

振德医疗联合浙江省医疗器械检验研究院科研团队为攻克医护人员面部压疮和提高佩戴口罩密合性的难题,启动了“高密合性面部防护产品压疮保护材料研究及基于三维扫描的新型产品研制”项目并成功申报省科技厅重点研发项目,通过夜以继日的研究和反复不断的测试,近日终于在新型水凝胶合成方面取得突破性进展。 水凝胶制备示意图 在新冠疫情进入常态化防控的当下,防护口罩已成为百姓日常生活必不可少的消耗品。而防护口罩的实际过滤效率,也就是人们常说的口罩质量被越来越多的社会大众所关注,同时也时刻牵动着振德医疗和监管部门的心弦。 在大量的口罩检测试验过程中,通过对防护口罩不合格原因的统计学分析发现,密合性是导致医用防护口罩不合格的主要性能指标,然而密合性不合格的最主要原因在于人们佩戴口罩过程中鼻夹处与面部贴合不完全。 此外,因疫情防控需要,奋战在抗疫一线的医护工作人员,因长时间叠加佩戴各种防护用品,导致面部局部受压缺氧,引起器械相关压力性损伤(DRPI),直接表现为皮肤红肿、疼痛、破损等症状。 为有效提升医护人员佩戴防护产品的安全性与舒适性,振德医疗作为行业领先企业,与浙江省器械院科研人员共同从用于压疮保护的新材料研究和产品研制两方面出发,通过不断合成、不断组合、不断尝试,最终筛选出具备优异的生物相容性且高强度、高延展性的水凝胶配方。 与此同时,振德医疗与浙江省器械院科研团队对新合成的水凝胶材料开展了压缩测试以模拟正常使用过程中材料受压情况,经不同测试环境的试验结果反馈,该水凝胶材料具有良好的稳定性和弹性。

水凝胶在甘油中浸泡不同时间后的照片(A)及拉伸性能(B);水凝胶的压缩性能(C-E)。

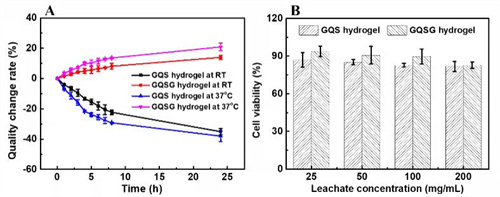

为进一步了解新型水凝胶材料的抗菌性能、保水性能以及可降解性能,科研团队结合性能指标开展了大量比对试验。试验结果表明该新型水凝胶材料均具备优异的表现。

未浸泡甘油的水凝胶(A)、浸泡甘油4 h的水凝胶(B)、浸泡甘油6 h的水凝胶(C)与市售伤口敷料(D)与大肠杆菌共培养24 h后,细菌在材料表面的黏附情况。(绿色部分为细菌)

(A)GQS水凝胶及GQSG水凝胶在室温下及37 oC下的保水性能;(B)GQS水凝胶及GQSG水凝胶的细胞毒性。

振德医疗将加强与浙江医院和浙江省器械院科研团队的合作,通过三维扫描技术及大数据分析技术设计完善压疮保护材料的三维立体形状,有效解决佩戴密合性不合格问题,切实提高广大医务工作者及社会大众佩戴防护口罩过程中的舒适性和安全性。